Description

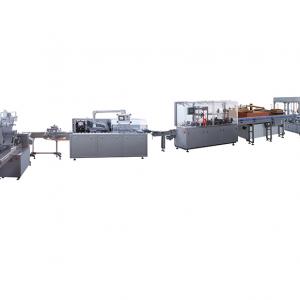

The fully automatic bearing packaging machine is suitable for automatic feeding and packaging of bottle shaped (round bottle, square bottle) items. The entire process of online automatic bottle sorting and transportation, manual folding (1 to 4 times folding) and transportation, manual detection, paper box suction and forming and transportation, material entry into the box, batch number imprinting, paper tongue packaging at both ends of the paper box (also applicable to hot melt adhesive), shortage removal, and finished product output are all completed automatically.

Technical parameters of fully automatic bearing box packing machine

Power supply: Ac380v three-phase four wire 50HZ

Total power: 1.5KW

Production capacity: Host running speed 30-100 boxes/minute

Folding machine running speed 30-100 boxes/minute

Gas consumption: 20m3/h (pressure 0.5-0.7mpa)

Packaging materials: quality of paper boxes; 250-450g/m2 (depending on the size of the paper box)

External dimensions: 3300x1350x1650mm

Weight: approximately 1.5 tons

Technical parameters of fully automatic bearing box packing machine

Power supply: Ac380v three-phase four wire 50HZ

Total power: 1.5KW

Production capacity: Host running speed 30-100 boxes/minute

Folding machine running speed 30-100 boxes/minute

Gas consumption: 20m3/h (pressure 0.5-0.7mpa)

Packaging materials: quality of paper boxes; 250-450g/m2 (depending on the size of the paper box)

External dimensions: 3300x1350x1650mm

Weight: approximately 1.5 tons