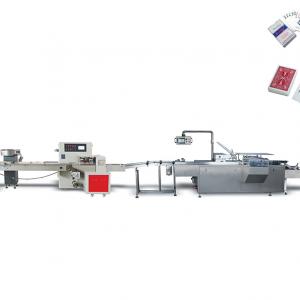

Description

This machine is suitable for packaging pharmaceutical aluminum-plastic plates, round bottles, opposite sex bottles, food, learning supplies, health products, toys, cosmetics, automotive parts, toothpaste, tissues, office supplies, hardware, household paper, poker, and similar items. It can automatically complete the folding of instructions, opening of paper boxes, item packaging, printing batch numbers, sealing, and other tasks.

Technical parameters for bag packaging machine

Power supply: Ac380v three-phase four wire 50HZ

Total power: 1.5KW

Production capacity: Host running speed 30-100 boxes/minute

Folding machine running speed 30-100 boxes/minute

Gas consumption: 20m3/h (pressure 0.5-0.7mpa)

Packaging materials: quality of paper boxes; 250-450g/m2 (depending on the size of the paper box)

External dimensions: 3300x1350x1650mm

Weight: approximately 1.2 tons

The main performance and structural characteristics of the bag packing machine:

1. Adopting automatic box opening (suction), folding instructions, cutting, feeding, batch number printing, box sealing, detection and waste removal processes, the operation is stable and the noise is low.

2. Adopting PLC and human-machine interface automatic control operating system, stepless frequency conversion speed regulation, high degree of automation, simple and easy to understand operation.

3. Adopting excellent electrical components for stable and reliable performance.

4. Adopting mechanical overload automatic shutdown function to ensure the safety of the machine.

5. Automatically remove packaging products that are missing packaging materials or instructions, ensuring the quality of the packaging products.

6. It has functions such as fault display, alarm, and finished product counting, making it easy to maintain and handle faults.

7. Various automatic feeders and conveying mechanisms can be designed according to customer requirements.

8. Optional hot melt glue machine can be equipped with hot melt glue spray sealing or design a hot melt glue brushing device.

9. It can achieve linkage production with aluminum-plastic packaging machines, pillow packaging machines, filling machines, soap making machines, spray coding machines (or regulatory code systems), labeling machines, online weighing machines, 3D packaging machines, heat shrink packaging machines, strapping machines, other production lines, etc.

Technical parameters for bag packaging machine

Power supply: Ac380v three-phase four wire 50HZ

Total power: 1.5KW

Production capacity: Host running speed 30-100 boxes/minute

Folding machine running speed 30-100 boxes/minute

Gas consumption: 20m3/h (pressure 0.5-0.7mpa)

Packaging materials: quality of paper boxes; 250-450g/m2 (depending on the size of the paper box)

External dimensions: 3300x1350x1650mm

Weight: approximately 1.2 tons

The main performance and structural characteristics of the bag packing machine:

1. Adopting automatic box opening (suction), folding instructions, cutting, feeding, batch number printing, box sealing, detection and waste removal processes, the operation is stable and the noise is low.

2. Adopting PLC and human-machine interface automatic control operating system, stepless frequency conversion speed regulation, high degree of automation, simple and easy to understand operation.

3. Adopting excellent electrical components for stable and reliable performance.

4. Adopting mechanical overload automatic shutdown function to ensure the safety of the machine.

5. Automatically remove packaging products that are missing packaging materials or instructions, ensuring the quality of the packaging products.

6. It has functions such as fault display, alarm, and finished product counting, making it easy to maintain and handle faults.

7. Various automatic feeders and conveying mechanisms can be designed according to customer requirements.

8. Optional hot melt glue machine can be equipped with hot melt glue spray sealing or design a hot melt glue brushing device.

9. It can achieve linkage production with aluminum-plastic packaging machines, pillow packaging machines, filling machines, soap making machines, spray coding machines (or regulatory code systems), labeling machines, online weighing machines, 3D packaging machines, heat shrink packaging machines, strapping machines, other production lines, etc.